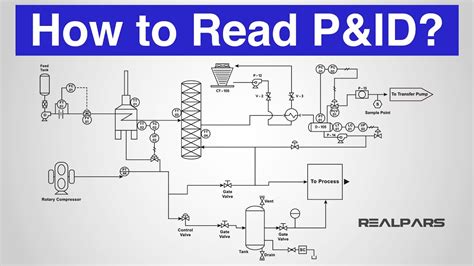

lv instrumentation diagrams | instrumentation and control diagram lv instrumentation diagrams P&IDs and loop diagrams are construction and documentation drawings that depict the flow of the process and illustrate the instrumentation control and measurement interactions, wiring and . Levequests are unlocked every 5 levels from level 1-45 and every 2 levels from 50 onwards. Starting Level 10, each batch of Levequests must be “unlocked” by speaking to the respective Levemete. They give you a trial Levequest (does not reduce allowances) to prove you’re up for the task.

0 · p&id instrumentation diagram

1 · instrumentation loop diagram

2 · instrumentation diagram abbreviation example

3 · instrumentation and control diagram

4 · industrial instrumentation diagrams

For more information or to register for a program, please call (702) 515-5367. “Meteor Showers and Storms”- The Las Vegas Astronomical Society will have member telescopes to view objects in our night sky. Bring your own telescopes or binoculars if you have them. You may also bring chairs for comfort and snacks. Dress for the weather!

Typically instrument abbreviations used in P&IDs consist of two letters: the first indicating the process variable and the second indicating the instrument/controller function. For example, the . A P&ID could be a detailed flow diagram of the processing unit, ancillary unit, an offsite product storage system, product loading system, or it could be a drawing of the process .

P&IDs and loop diagrams are construction and documentation drawings that depict the flow of the process and illustrate the instrumentation control and measurement interactions, wiring and . P&ID diagrams (Piping and Instrumentation Diagrams) provide a schematic representation of the functional relationship between piping, instrumentation, and system .Definition: “A schematic diagram of the relationship between instruments, controllers, piping, and system equipment.” (Kirk, Weedon, & Kirk, 2014, p. 23) P&IDs are a symbol based schematic .To further understand instrument abbreviations used in instrumentation and process diagrams, we have presented more examples of the common combinations of instrument abbreviations you .

p&id instrumentation diagram

The Process and instrumentation diagram, commonly known as a P&ID, shows the connections between process equipment. The diagram indicates the flow directions, safety .Learn How to Read Piping and Instrument Diagram-P&ID, Process Flow Diagram and Block Flow Diagram used in Process Plant.Typically instrument abbreviations used in P&IDs consist of two letters: the first indicating the process variable and the second indicating the instrument/controller function. For example, the instrument abbreviation “PI” denotes a “Pressure Indicator”.

A P&ID could be a detailed flow diagram of the processing unit, ancillary unit, an offsite product storage system, product loading system, or it could be a drawing of the process and instrumentation system that connects different operating facilities together.P&IDs and loop diagrams are construction and documentation drawings that depict the flow of the process and illustrate the instrumentation control and measurement interactions, wiring and connections to the process. The process is illustrated in . P&ID diagrams (Piping and Instrumentation Diagrams) provide a schematic representation of the functional relationship between piping, instrumentation, and system components within a project. They offer a detailed overview of the process flow, including equipment, valves, and instrumentation, crucial for design and operational understanding.Definition: “A schematic diagram of the relationship between instruments, controllers, piping, and system equipment.” (Kirk, Weedon, & Kirk, 2014, p. 23) P&IDs are a symbol based schematic language that once understood, adds simplicity to the information being presented. They can also be confusing when a unique symbol appears.

To further understand instrument abbreviations used in instrumentation and process diagrams, we have presented more examples of the common combinations of instrument abbreviations you may likely come across. The Process and instrumentation diagram, commonly known as a P&ID, shows the connections between process equipment. The diagram indicates the flow directions, safety and control measures, and pressure ratings of a system through visual symbols.Instrumentation: The instrumentation includes sensors and other devices that measure process parameters like pressure, temperature, and flow rate. The information is used to provide feedback to the controller and ensure the desired flow rate is maintained.

Below Table 3 shows some instrument abbreviations for devices like switches, alarms, transmitters, solenoids, relays, primary elements, test points, probe, view glass, as well as final elements. What do Tag Numbers on P&ID Diagrams represent?Learn How to Read Piping and Instrument Diagram-P&ID, Process Flow Diagram and Block Flow Diagram used in Process Plant.

Typically instrument abbreviations used in P&IDs consist of two letters: the first indicating the process variable and the second indicating the instrument/controller function. For example, the instrument abbreviation “PI” denotes a “Pressure Indicator”.

A P&ID could be a detailed flow diagram of the processing unit, ancillary unit, an offsite product storage system, product loading system, or it could be a drawing of the process and instrumentation system that connects different operating facilities together.P&IDs and loop diagrams are construction and documentation drawings that depict the flow of the process and illustrate the instrumentation control and measurement interactions, wiring and connections to the process. The process is illustrated in . P&ID diagrams (Piping and Instrumentation Diagrams) provide a schematic representation of the functional relationship between piping, instrumentation, and system components within a project. They offer a detailed overview of the process flow, including equipment, valves, and instrumentation, crucial for design and operational understanding.

Definition: “A schematic diagram of the relationship between instruments, controllers, piping, and system equipment.” (Kirk, Weedon, & Kirk, 2014, p. 23) P&IDs are a symbol based schematic language that once understood, adds simplicity to the information being presented. They can also be confusing when a unique symbol appears.To further understand instrument abbreviations used in instrumentation and process diagrams, we have presented more examples of the common combinations of instrument abbreviations you may likely come across. The Process and instrumentation diagram, commonly known as a P&ID, shows the connections between process equipment. The diagram indicates the flow directions, safety and control measures, and pressure ratings of a system through visual symbols.Instrumentation: The instrumentation includes sensors and other devices that measure process parameters like pressure, temperature, and flow rate. The information is used to provide feedback to the controller and ensure the desired flow rate is maintained.

instrumentation loop diagram

instrumentation diagram abbreviation example

instrumentation and control diagram

coffret parfum burberry baby touch

Yes, Servants are designed to do what they’re supposed to do without the help of extra levels or append skills. Yes, leveling past 100 and unlocking append skills are ultimately just flexes that show off how insanely willing you are to .

lv instrumentation diagrams|instrumentation and control diagram